Source: CISDI

Case 1

study with our ops mgt. services applied to an overseas steel plant:

Ironmaking problem: a low hot metal output, operating with a high cost

Factored in: production organization in upstream-BF and blast furnaces, process quality control, operation and equipment maintenance

- Upstream-BF

-

Coking

1. Coke output was not enough

2. Moisture was varied in a range of 7% to 12%, causing a large fluctuation of BF status

3. Instable thermal property of coke was remained severely even over a long period after blow-in

Sintering

1. Sinter output was not enough

2. Sinter compositions were not stable Sinter's grade and variable basicity and unstable contents of Al2O3 created BF's instability for operation.

3. Sinter's grain size was not favorable. Sinter's sampling average size less than 20mm, against BF's permeability, forcing the BF to operate with a pressure difference of 200kPa plus for long

Prominent problem: Low output High cost

- Blast furnaces

-

Operators for the casthouse and blast furnaces were not experienced

BF operation

1. Unable to judge the trending status

2. Inexperienced in prevention from and resolution of troubles or accidents

3. Lack of coordination and integrated management on BF proper, casthouse and other systems

Equipment maintenance

1. No professionals for equipment maintenance, mostly shifted duty from equipment installation

2. Simplified checking to detect or predict equipment failures

3. Inefficient troubleshooting due to lack of response experience

Case 2

Our tech optimisation services for a wire-rod mill

-

Solution and services:

Optimize the production technology by reducing intermediate losses

-

Results:

Increasing the yield by 0.5% for the first year after optimization, top of China's fellow traders

Creating another USD 1.15 million profit for the first year and beyond

Case 3

Our tech consulting services enable a cold mill and a hot-dipped galvanizing line to achieve all set targets

- Cold rolling mill

-

CGL units that failed to produce desired products have been corrected, modified and optimized to achieve highest ever output, product quality and cost efficiency.

One year of technology consulting services experienced the unit diagnosis and assessment, correction and modification, cold and hot commissioning, continuous optimization and training.

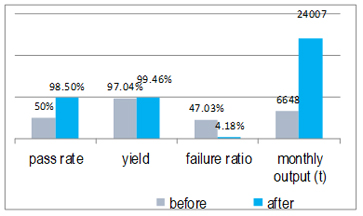

The chart below shows the optimized figures from the former deficiencies.

- CGL

-

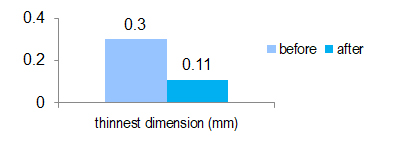

One year of technology consulting services has resulted

The product's extreme thickness has been reduced from 0.3mm to 0.11mm, successfully expanding the product mix.

Zinc pot's slag output ratio has been decreased by at least 5%, saving the line's production cost.

The line's productivity has been improved by 20% as a minimum.

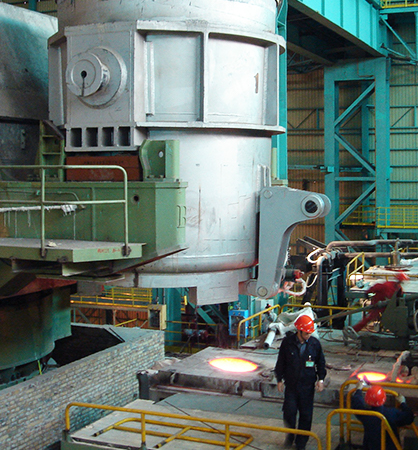

Case 4

Our refractory services for a steelmaking shop

- The services we provide are:

- EPC-based services for the steelmaking refractory with their settlement by prices of the total heats

- Building of the BOF refractory

- Gunning of the trunnion refractory

- Changing the taphole and refractory spraying with the customer's assistance.

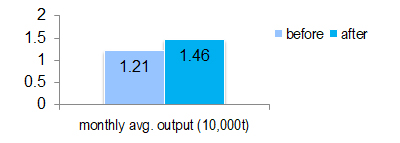

- The achievements thanks to our services:

- Our EPC-based services are integrated procurement, management, application function and service life and distribution and maximises the procurement services to values

- The shop's annual output is increased by around 13%

- The refractory service life extends by 1.5 to 2 times

- The refractory maintenance costs are reduced by 30%.