Source: CISDI

Our services are presented mainly by the following three types:

-

Production technology services

We dispatch client-needed technological and production experts to render instructions on site bottlenecks. They work for improving production stability and assist the client in achieving production targets.

-

Unit-wise production management services

We are responsible for designating organisations for individual plant's production, managements on equipment and facilities, process optimisation and improvements of operation and control and for setting KPIs.

-

Plant-wide holistic operations services

We are responsible for plant-wide operations management and setting KPIs for the contractual management scope.

Our ops management solutions pursue to transform conventional production to innovation-driven, quality & efficiency competitive, green and services-oriented.

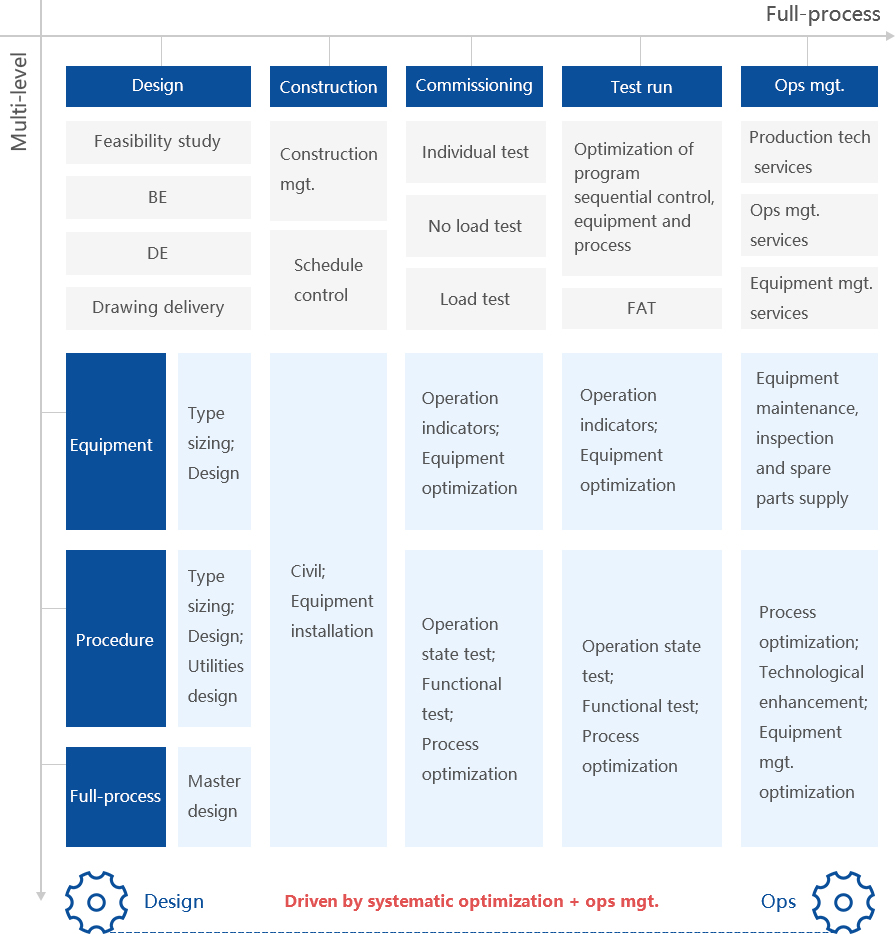

They feature multiple levels, full processes and dual engines as shown in the chart below.

We provide continuous ops management services for improving steel's competitiveness.

The main dimensions to be improved are:

-

- ① Cost performance

-

Capacity/size defined

Process configuration

Equipment type sizing

Ramp up

Organization & coordination

Scheduling events

Quality monitor and control

-

- ② Continuously improved operations

-

Production management and quality process control

System building and improvement

Fostering specialized workforce

Product upgrade and specification expansion

Improved product quality

Improved production efficiency (output)

Reduced equipment failure ratio

Reduced production cost

We provide continuous improvement services for production line operations and supply chains by relying on our OM team's design, R&D, and resources integration capabilities.

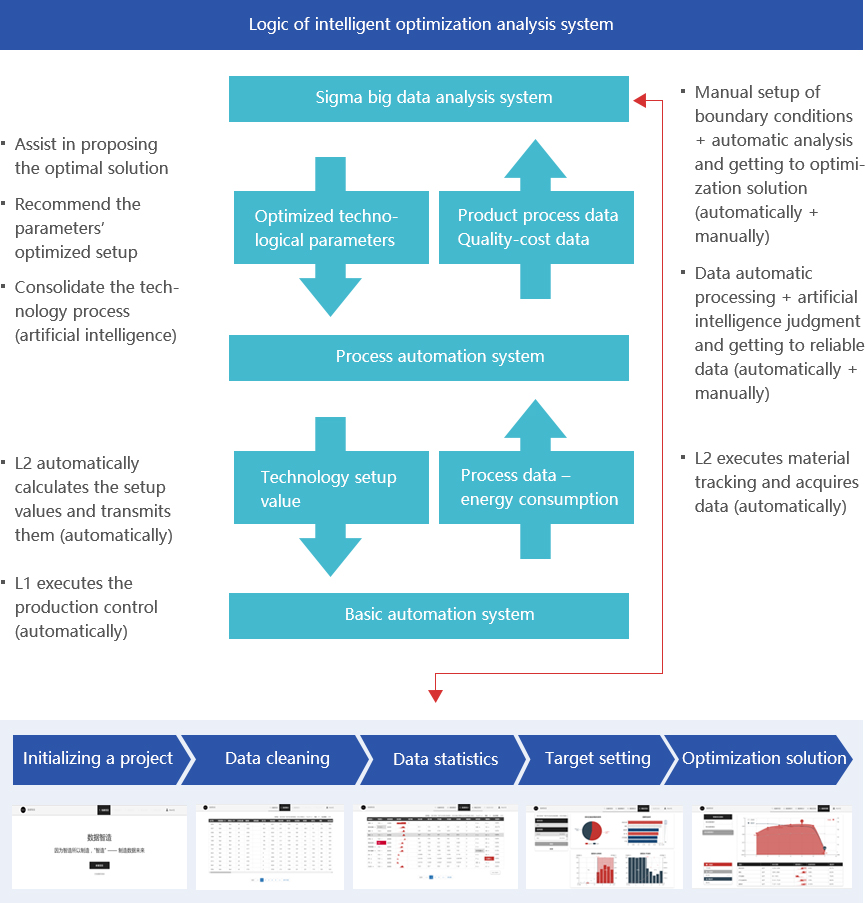

Our intelligent optimisation analysis system is used for solving operation issues in an economical and efficient way.