CISDI solutions – The Future of Steel-Making at METEC 2023

Date:2023/8/24 Source: CISDI

In June, companies from around the world flocked to Dusseldof to attend a host of important steel trade fairs.

GIFA, the International Foundry Trade Fair, and METEC, the world’s leading trade fair for metallurgy, were staged, along with thermo processing technology fair THERMPROCESS 2023 and the leading precision casting products event, NEWCAST 2023.

At these highly-respected exhibitions, around 2,200 companies showcased their latest skills and developments to over 60,000 visitors from 114 countries - 58 per cent of whom are classed as industry decision-makers.

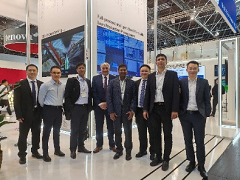

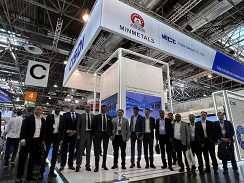

CISDI was in attendance at METEC 2023, where themes of sustainability and artificial intelligence dominated the exhibition halls.

The Chinese metallurgical giant took a large stand and seized the opportunity to exchange views with global steel enterprises and fellow traders. The hot topics for discussion were the challenges of ferrous metallurgical sustainable development and how to deepen mutual cooperation.

CISDI’s stand, themed The Future of Making Steel, impressed visitors with its display of advanced solutions and the company’s innovations in consulting, green and low carbon development, intelligent manufacturing, core tech and equipment.

CISDI’s stand at METEC 2023

CISDI’s METEC stand became a hub for the meeting of minds and opinions

² The route to systematic, cost-effective and tailor-made green steel tech

Emergent issues including the effective use of resources, energy conservation, carbon reduction and response to climate crisis predominated at this year’s METEC.

As leading transformers of conventional steel processes to green and low carbon, CISDI showcased its systematic, cost-effective and tailor-made green steel solutions, which combine green energies with steel production to achieve carbon reduction, super-efficient utilisation of resources and ultra-low emissions.

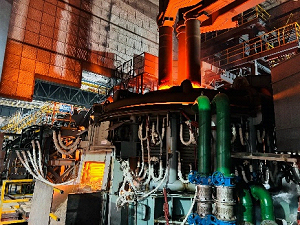

To meet today’s steel manufacturing needs and environmental protection challenges, CISDI has unveiled its hydrogen-based shaft furnace, the low-carbon blast furnace, the green EAF and green power products. Their advanced tech and economic indicators made a positive impact at the exhibition.

CISDI’s new star product the AuoARC EAF for scrap melting, consumes two thirds less energy than a conventional blast furnace and basic oxygen furnace process and produces only a third of the emissions.

The AutoARC EAF’s upgrade - the SuperARC EAF - is showcasing eye-catching indicators - an electric consumption of 250 to 300kWh per tonne of liquid steel and a tap-to-tap cycle of 25 to 30 minutes.

Visitors were impressed by CISDI’s green and low-carbon section, where specialists explained its Clever Carbon tech route and model and its ability to search for a tailor-made carbon reduction route by inputting a plant’s energy and resource conditions.

An AutoARC CISDI EAF in operation at a Chinese steel plant is achieving the following world-class indicators:

ü Power consumption of 335kWh per tonne of liquid steel with 100% scrap melting

ü A tap-to-tap cycle of within 35 minutes

ü An electrode consumption of 0.85kg per tonne of liquid steel.

² The digital, intelligent factory created by CISDI is a world-leader

CISDI’s digital and intelligent factory solution pursues ultimate efficiency. This unique world solution is applicable for a full-process steel manufacturing plant and its individual procedures.

A sample factory is the operational Yongfeng Steel Lingang plant in Shandong Province, but at METEC it was in the limelight as an outstanding demo of the full-process smart plant.

The plant has an integrated, centralised control system covering 17 major procedures, which collects 240,000 points of plant-wide data into a unified industrial internet platform.

A full gamut of production processes involving 30,000-plus sets of equipment, over 400 posts and around 2,000 smart APPs are now under unified operational and production management.

Thanks to this unique smart tech and product, Yongfeng Lingang has achieved the world’s benchmark of over 1,600 tonnes of per capita annual output.

CISDI’s stand featured a simulated, centralised control centre to showcase multiple intelligent manufacturing projects - the ECIA stockyard, ICC ironmaking, smart rolling and autonomous hot metal locomotive, and the unified full-process digital platform – all of which are world firsts.

The centralised control centre at Yongfeng Lingang was built by CISDI as a digital, lean production plant based on the unified full-process digital platform, and is achieving a per capita annual output of more than 1,600 tonnes

² Total solutions for cost and tech competitiveness

Front-end consulting and engineering has a major impact on a steel plant’s future competitiveness.

CISDI’s consulting-led total solutions provide optimal answers to the issues of systematic, economic and sustainable developments.

Some 50 steel enterprises around the globe have applied CISDI’s systematic optimisation solution, which has five flows at its centre (iron, energy, mass, discharge and information flows).

The total production capacity served has surpassed 400 million tonnes a year and CISDI’s solution has helped customers reduce costs by around US$ 1.388 billion per annum.

At the METEC exhibition, CISDI presented case studies on its large-scale steel projects - Formosa Ha Tinh Steel in Vietnam, ASSB in Malaysia, and China’s Baosteel Zhanjiang and Zenith Nantong.

A virtual reality system enabled visitors to experience virtually CISDI’s latest green, smart steel plant in China, for which CISDI delivered front-end consulting, systematic engineering, digital management and high-quality delivery solutions.

Zenith Nantong Steel – the world’s largest greenfield steel plant

CISDI contributed to the Jiangsu Province coastal project’s green, quality, efficiency and intelligent credentials

² Praise rolled in for CISDI’s core tech and products

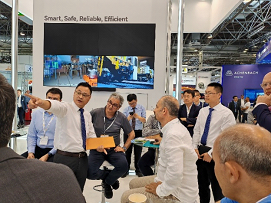

CISDI’s stand staged more than 30 sessions during the five-day exhibition. During these events, long-standing partners including ArcelorMittal, Tata Steel, Nippon Steel & Sumitomo Metal Corporation and a host of new clients visited to find out about CISDI’s stunning new innovations.

A top executive from an Indian plant took the opportunity to consult the CISDI team about a steelmaking solution his company needed. CISDI reported that he was particularly impressed when a pertinent product list was quickly called up from an onsite system. The team was able to demonstrate how a design, supply and service would result in higher labour productivity, zero liquid discharge and lower losses during raw material transport.

This potential client was impressed by the fast response and intimated an interest in holding further more detailed discussions.

The VR system exploring Yongfeng Lingang’s centralised control centre proved very popular with visitors and prompted one UK steel expert to comment: “This is the future of the world’s steel production.”

Other positive comments recorded from visiting customers included:

We are seeing really advanced tech indicators!

This is the steel plant I dreamed of.

Fantastic new tech and solutions!

Our project is running smoothly because of CISDI’s design and execution.

Mr Lakshmi Mittal, chairman of ArcelorMittal, and Mr Peng Xiao, president of CISDI, are pictured at CISDI’s METEC stand

Mr Ketan Bansal, vice-president of ArcelorMittal, is pictured at the CISDI stand

Mr Naveen Jindal, chairman of JSOL, also visited CISDI’s stand

Mr Neeraj Kochhar, chairman of VIRAJ, with CISDI

Mr Sajjan Jindal, chairman of JSW Steel, with CISDI

The CISDI team met with Aarti Steels

The team with Mr Avneesh Gupta, vice-president of Tata Steel visits the CISDI booth

Meeting with Mr Zarir Chacha, the executive of Special Projects Tata Limited

Mr Nguyễn Viết Thàng, CEO of Hoa Phat Group Vietnam, talks with the CISDI team

The top executive of OYAK Turkey meets with the CISDI team at the booth