Intelligent Stockyard

Date:2020/12/23 Source: CISDI

CISDI has taken the lead in turning the global steel industry’s need for intelligent, eco-friendly stockyards from goal to reality.

After years of research and development into processes to ensure clean storage of stock materials, clean production and intelligent manufacturing methods, CISDI have played a key role in over 90 stockyard engineering and construction projects.

These stockyards are now handling bulk materials for around 400 million tonnes of annual production capacity around the globe.

CISDI’s intelligent, eco-friendly stockyard tech and equipment has won over 70 per cent of the world’s market share.

Tech highlights range from intelligent decision-making for an optimised process to intelligent blending and proportioning, unmanned stacking and reclaiming onsite operations, the digital stockyard, 3D online production simulation and automated patrol checks for the belt conveyor.

CISDI’s intelligent stockyard tech aims to achieve four objectives – efficient transportation, unmanned onsite operations, digital storage and refined management.

It has resulted in an 80 per cent reduction in labour requirements for stacking and reclaiming operations, a 10 per cent reduction in overall energy consumption and a 10-20 per cent increase in efficient land use.

✧ Intelligent decision-making on optimised process

Intelligent decisions on optimal process flow/route

One-button selection

Intelligent running of the belt conveyor

Full-process, automated tracking

✧ Unmanned stacking and reclaiming onsite

Remote control of stacker/reclaimer equipment

Automated stacking

Automated reclaiming

Integrated, interlocked systems

✧ Digital stockyard

Builds real-time, digital models for the stock piles

Automatically drafted 3D yard drawings

Automatic, real-time inventory checking

✧ 3D online production simulation

Modelling and simulation at design phase

Online simulation at production phase

Preview of the production plan regulations

References:

China:

Baowu Zhanjiang Steel, Shandong Laiwu Steel, Baowu WISCO, Masteel and Baotou Steel

Vietnam:

Formosa Ha Tinh Steel

Malaysia:

ASSB

The world’s first intelligent stockyard at Baowu Zhanjiang

CISDI’s patented intelligent stockyard has been operating at Baowu Zhanjiang from December 2016.

Systems for intelligent decision-making on optimised process, intelligent blending and proportioning, unmanned stacking/reclaiming onsite operations, digital stockyard and 3D production simulation have achieved an annual receiving capacity of 350 million tonnes on a footprint of 1.011 million square metres.

Zhanjiang’s stockyard project has been expanded and incorporated with new intelligent products in line with its new construction phase.

It has further reduced its workforce while improving overall efficiency, safety and reliability.

This intelligently-operating stockyard has been included into Zhanjiang Steel’s integrated, centralised controls, seeing more operation cost savings and increased stacker/reclaimer’s availability as a result of decreases in energy usage and idle equipment.

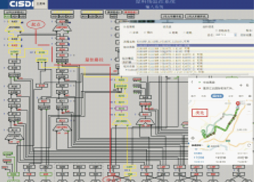

The CISDI-patented intelligent stockyard in operation at Baowu Zhanjiang Steel

The critical tech applied at Zhanjiang stockyard:

Intelligent decision-making on optimised process flow/route

Intelligent blending and proportioning

Belt conveyor automated patrol check

Digitalised stockyard

Unmanned onsite operations at stacking and reclaiming

Online simulation for production.

Results and benefits achieved:

Operations reach higher quality standards

Labour productivity is increased by around 80 per cent

Yard’s availability is enhanced by around 20 per cent

Energy consumption is reduced by 5-10 per cent

Inventory checking is 90 per cent more efficient.