Hot strip mill relocated to Baosteel Desheng goes into pilot phase

Date:2020/11/10 Source: CISDI

A 1,780mm hot strip rolling line has entered pilot production after a successful hot commissioning at Baosteel Desheng Stainless Steel.

The line has been relocated from Baosteel Shanghai to Desheng in the Fujian Province.

Desheng is a major base in Baowu’s strategy to produce 100 million tonnes a year and is being expanded and upgraded to a green producer of high-quality stainless steels.

The line is the first project to go into operation at Desheng. CISDI was the total technological solutions provider and the package supplier of its reheating furnace, main rolling machinery and electric and automation system.

The line’s production capacity will reach 4.20 million tonnes a year, one million more than its original output in Shanghai.

Upgrades:

• New pair-cross-roll mill with reaction block and shifting systems

• New 2-hi reversing roughing mill E1R1 with an edger roll, the most powerful hot continuous rolling equipment in China, with world-class strength

• Process design of hot coiling box, edge heater plus insulating hood

• Rebuilt finishing mill stand 5-7 PC type to stationary mill train with reaction block and shifting systems, an efficient reuse with the addition of strip profile control

• Upgrade of descaling unit by increasing its nozzle outlet pressure to 28MPa to improve product surface quality

• Optimised dedusting systems for the roughing mill and finishing mill benefits the environment and makes maintenance simpler

• Optimised mill cooling water system to extend rolls service life and improve product quality

• Tightly controlled construction schedule to ensure a fast track to hot commissioning.

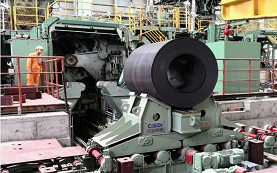

CISDI-supplied rolling mills in operation at Baosteel Desheng stainless steel’s 1,780mm hot strip rolling line