Handan Zhuoli ready to produce ultra-thin tin for food industry

Date:2020/3/9 Source: CISDI

Handan Zhuoli Fine Plate Co. has successfully hot-commissioned its

high-speed tin plate continuous annealing line in China’s Hebei Province.

CISDI supplied the electrics, instrument and computer system for the

Tin-CAL, China’s first with an EIC system designed and supplied by a Chinese

company.

The ultra-thin tin plate produced is a new material for the food

industry. Its thickness ranges from 0.17 to 0.55 millimetres and its width from

700 to 1,050 millimetres.

Production technology and technical indicators are the best in China.

The maximum process speed is 500 metres a minute - more than double the speed

of conventional lines - and the plant is capable of producing 250,000 tonnes a

year. Sheet tension can be well-controlled during production.

The CAL is configured with the following equipment:

- Dual payoff reels

- Automatic welder

- Multi-stage cleaning units

- Multi-tower vertical looper

- Gas/electric-heating vertical annealing furnace

- Water quenching unit

- Flying shear

- Dual re-coiler

CISDI’s EIC package includes design and supply of the electric drive and

automation – basic automation system (L1), instrumentation and process computer

system (L2) software programming and commissioning.

To ensure it became the most competitive line in China, CISDI applied

tailored expertise featuring the cleaning section’s tension control, the multi-tower vertical

looper’s tension and leveling control, the vertical annealing furnace’s tension

and temperature control, flying shear’s control and material precision

tracking.

To greatly improve the line’s production continuity and stability, CISDI

came up with a technological breakthrough - a unique tailored solution which

enables the motor drive unit for the furnace rollers to switch between

two vector control

modes: In the event of an encoder failure,

the motor can

switch to a vector control mode which has no encoder.

Zhuoli’s Tin-CAL is CISDI’s first successful application of its

cold-rolling expertise for the food packing sector. It comes on the heels of

two major successful applications for the high-end automobile and home

appliances sheet industry.

CISDI has become a major player for developing cold-rolled products

which create more precise, refined and better-quality production.

It lists China’s Pangang, WISCO, Guofeng Steel, Bayi Steel and Ganglu

Steel as clients. CISDI has created EIC systems for the continuous

galvanizing line at Vietnam’s TDA works, the CGL for Indonesia’s Sunrise plant and TATA

Metal, also in Indonesia.

The Tin-CAL at Handan Zhuoli

Tin coil produced from Zhuoli CAL, which is destined for the

food-packing sector

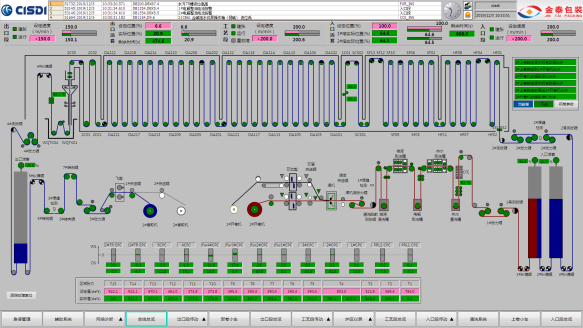

A screenshot from CISDI’s cold rolling control HMI for Zhuoli Tin-CAL

CISDI’s team, pictured with hot-tested tin coil at Zhuoli Tin-CAL