S&T: Deposit welding Robot is commissioned at SFRE

Date:2019/2/5 Source: CISDI

Deposit welding Robot is commissioned at SFRE

CISDI teams have created a robot capable of high-quality deposit

welding.

During pilot tests, the robot was able to perform surface deposit

welding on wedges, guides and support sleeves.

It has now been handed over to SFRE and is in commission in one of its

workshops, where the robot’s welds are so reliable, no defects have been

detected by the surface flaw inspector.

Copper surface deposit welding prevails at SFRE. However, it’s a

dangerous task; high-heat toxic gas, metal steam and metal dust are generated

which are dangerous to workers’ health. Producing welds of consistent quality

also requires a high level of skill and labour and procedure-transfer costs can

be high.

The Robot can complete non-standard copper deposit welding at one duty

position and reduces manpower.

CISDI will transplant the knowledge it has gained into other

metallurgical robot developments.

Deposit welding

robot fact file:

Applicable for non-standard copper deposit welding in a single piece and

in small batches, with diverse varieties and without clamps, and also for the

automatic deposit welding of carbon steel and stainless steel

Stable and reliable quality

Gives a high degree of flexibility. The robot can be adapted for various

shapes of surface deposit welding and for non-standard, clamp-free and

positioning-free pieces

Easy training – no need for repeat programming

Much less labour-intensive

Can be programmed offline

Capable of deposit welding on curves in a complicated space

Below; comparisons between robot-work and manual deposit welding:

|

Method |

Efficiency |

Quality |

Human Risk |

|||||

|

Rectangular surface 230mm×85mm |

Triangular

surface 230mm,

70mm |

Long

bar surface 1,180mm×20mm |

||||||

|

Robot |

Preparation time (min.) |

Welding time (min.) |

Preparation time (min.) |

Welding time (min.) |

Preparation time (min.) |

Welding time (min.) |

Reliable and stable, a high first pass rate, zero re-working |

No human involvement |

|

8 |

32 |

5 |

11 |

6 |

25 |

|||

|

Manual |

Welding time (min.) |

Welding time (min.) |

Welding time (min.) |

Unstable quality, a low pass rate, a high re-working rate |

High risk of severe injury

from toxic gas and metals dust |

|||

|

50 |

25 |

45 |

||||||

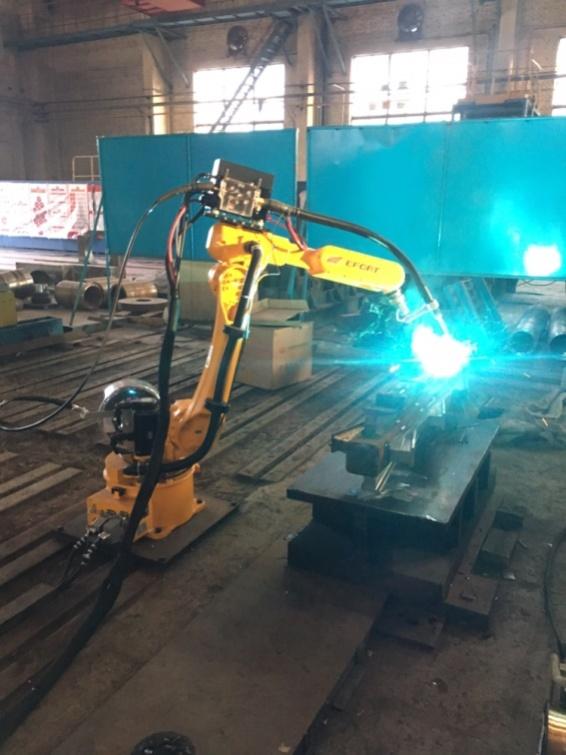

The rotary arm of a deposit welding

robot in action

The working plane of a deposit welding robot

Wedges with deposit welding completed by the robot

A drum with deposit welding performed by the robot