CISDigital AI Eyes - ‘all-seeing’ throughout Rizhao Steel’s manufacturing processes

Date:2024/4/18 Source: CISDI

CISDI is to build a machine vision-applied demo at Rizhao Steel in China’s Shandong Province.

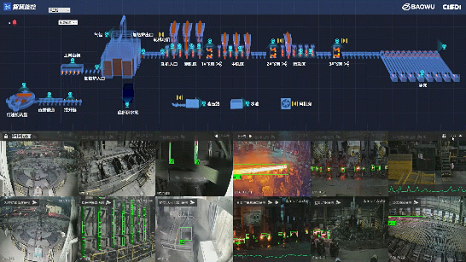

CISDigital AI Eyes are designed to operate throughout all major manufacturing processes, from stockyard to ironmaking, melting and rolling. Over a hundred visual recognition points are set for stockyard and BOF particle sizes, flame, steel ladle temperature, hot-rolled camber and coil code.

CISDigital AI Eyes products and benefits:

w The AI edge computing-based smart camera can automatically judge and recognise diverse manufacturing scenarios. It will help to stabilise operational quality and reduce lengthy screen-times for employees, ensuring a safer production.

w CISDigital AI Eyes generates moderate or high-definition images during complicated steel manufacturing processes. Its rendered video-streaming and deep-learning model can identify what images are required with high accuracy and to within 150 milliseconds.

w The Eyes algorithm gives highly accurate identification. As an example, flame’s status identification has an accuracy rate of over 99.5 per cent.

The AI Eyes have achieved standout results at Baowu Shaogang and Chongqing Steel, Pangang, Baotou Steel, Yongfeng Steel, Maanshan Steel and Hanzhong Steel.

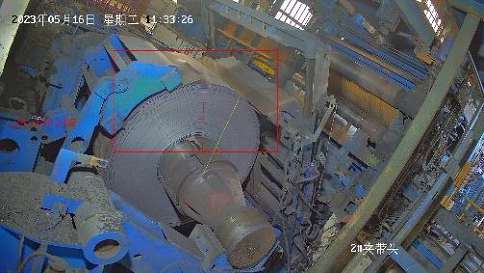

Coil’s unwinding angle is captured by the CISDigital AI Eyes

The AI Eyes enable production line smart sensing, which aids decision-making