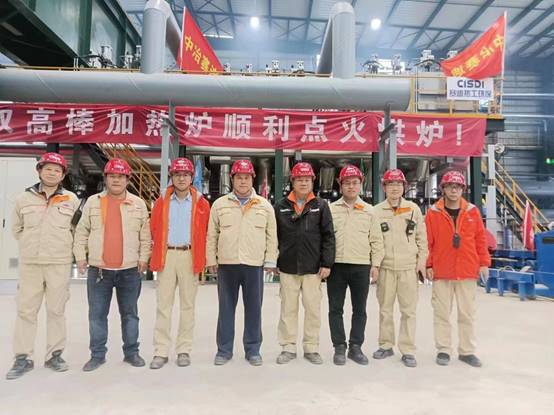

Reheating furnace drying off at Zenith Nantong’s dual-high-speed bar mill 1 is already world-class

Date:2023/1/17 Source: CISDI

World-leading technical, economic and emission indicators have been achieved at a CISDI-built reheating furnace for Zenith Nantong Steel’s dual-high-speed bar rolling line 1.

The low-carbon smart furnace has dried off, the last milestone before operation, and is hitting world-class targets as a result of CISDI’s applied technologies - blast furnace gas dual-regenerative combustion, sectionalised centralised reversing, dynamic and optimal ratio of air to fuel, and zoned temperature control.

CISDI was contracted to build four reheating furnaces for Zenith Nantong, which is based in China’s Jiangsu Province.

The furnace for the high-speed wire-rod mill 1 has been operating smoothly since August and the furnace for dual-high-speed bar mill 2 went into operation successfully in October.

Construction has already begun on high-speed bar mill 1’s reheating furnace.

CISDI’s project management team is now doubling down to prepare the dried furnace for hot commissioning and operation, and ensure construction of the remaining furnace is on-schedule.

The project management team at Zenith Nantong’s reheating furnace site is now working on the last furnace’s construction