First coil passes new intensive heat treatment line at Baosteel

Date:2023/1/17 Source: CISDI

CISDI has supplied a new, intensive heat treatment line for Baosteel’s 2,050mm hot rolling mill in Shanghai.

The first coil has been discharged successfully after continuous heat treatment.

The line is the first to be built in China to hit targets for high strength, optimal quality, super efficiency and intelligent application. Its production is completely continuous, short-process and efficient. Optimal quality product and reduced costs have been achieved.

Annual production of thin, high-strength specifications, ranging 2 to 6 millimetres thick, 900 to 1,700 millimetres wide and a maximum tensile strength of 1,800MP, will reach 100,000 tonnes - at least twice that produced by a conventional line.

In addition, carbon emissions will be reduced by over 30 per cent.

It is China’s first ultra-high-strength hot-rolled strip to be fully continuously heat-treated and feature intelligent operation and reduced manpower. These achievements are thanks to the following:

Core tech and equipment – intensified straightening, laser welder, shot blasting machine, non-oxidizing furnace, air atomisation and water quenching, fast induction heating and powerful coiler;

Other automated technologies - smart coil preparation station, coil’s automatic identification and tracking, automatic loading and automatic pay-off reel, threading and welding, straightener and process section’s model control, automatic whipping and automatic sampling, coiling and unloading.

The line’s products - high-strength structural, wear-resistant, shielding and low-stress tempered steel coils - will be widely used by manufacturers of construction machinery, dumping, heavy-duty trucks and armoured security vehicles.

The line’s success underscores CISDI’s leading role in advancing China’s ultra-high-strength strip heat treatment and finishing sector.

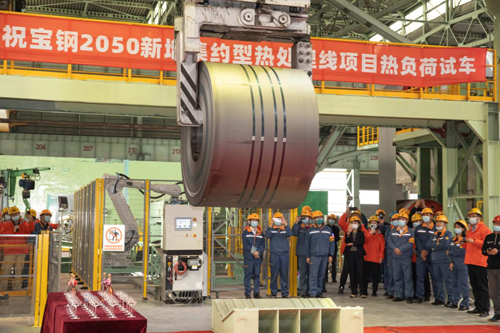

A CISDI-supplied intensive heat treatment line, newly installed at Baosteel’s 2,050mm hot strip mill

The first coil is discharged from the new heat treatment line

CISDI’s project management team, pictured at the heat treatment line