CISDI’s low-carbon EAF set to become a star product

Date:2021/8/23 Source: CISDI

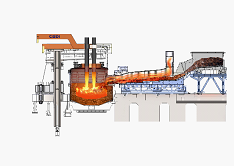

CISDI’s super green electric arc furnace is about to see its first industrial application at a steel plant.

A 40-tonne AC EAF at Pangang’s Changcheng Special Steel is being transformed to a low-carbon, DC electric version by CISDI.

It will lower production costs and increase production capacity.

CISDI’s tech solutions will reduce the tap-to-tap cycle and lower energy and electrode consumption required for melting when charging special raw materials and producing special steels.

CISDI has made multiple breakthroughs in process and equipment for EAF systems:

- integrating needle-bottom anode, graphite electrode top cathode and

new-type

insulated gate bipolar transistor (IGBT) technologies

- applying modular DC power supply to improve power reliability and furnace productivity.

These systematic innovations solve the problems of a full-scrap melting furnace:

- high energy and electrode consumptions, high impacts on grid

- conventional IGBT’s capacity against impact, fault and loss and consumption.

The new-type modular IGBT enables melting’s power factor to be higher than 0.95 and achieves step-less regulations for current and voltage, greatly reducing electrode and power consumption for melting.

As a result, the tap-to-tap cycle is shortened by 20 minutes.

Strong stirring of the DC arc strengthens the melting bath’s stirring effect, bringing higher iron and alloy yields.

The super green EAF is now being manufactured at CISDI.

Its digital, smart and green features represent a new route for EAFs of the future, targeting enhanced quality and efficiency while reducing energy and consumption.

A model for the CISDI-AutoARCTM - featuring innovative cascade charging and green manufacturing