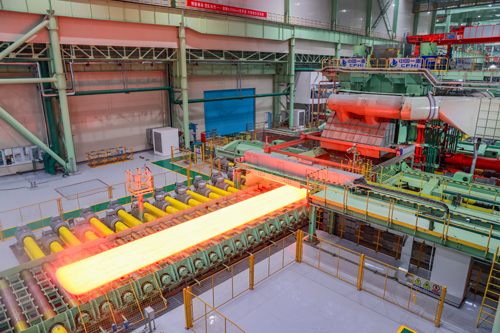

JISCO’s heavy plate mill wraps up, thanks to CISDI’s capabilities

Source: CISDI

A wrapping-up ceremony at Jiuquan Iron and Steel Co celebrated the build of its Hongxing melting and rolling upgrading and product mix optimisation programme.

The Gansu Province’s programme marks JISCO’s forward strides to achieving higher standards of product orientation and smart and green manufacturing.

A 4,200mm-spec heavy plate rolling line was hot commissioned just before the celebratory event. Over 20 items of CISDI’s advanced processes and equipment have been applied, a leading level in China. They include:

- High-rigidity heavy plate mill with a large rolling moment

- Smart, reliable dual-regenerative reheating furnace

- High-pressure water descaling machine, featuring super-efficiency and energy-saving

- Ultra-fast cooling unit

- Online automatic flaw detection equipment

- Oxidation-free, roller-hearth heat treatment furnace

- Roller quenching device.

Taking technological leadership, CISDI is the EPC-based service provider for the programme’s four major plants - steelmaking and continuous casting; a 4,200mm-spec heavy plate mill; an 80,000m3 gas holder and reclaimed water deep processing.

The programme broke ground in February 2024 and hot testing of its steelmaking and continuous casting plant was carried out in April 2025, with its heavy plate mill following just four months later. The gas holder and the water plants were hot tested in the first half of this year.

The meltshop will achieve an annual slab production capacity of 2.30 million tonnes.

The heavy plate mill will be able to produce 1.20 million tonnes annually, featuring a plate thickness range of 6-100mm and a width range of 1,500-3,800mm.

The main heavy plates - high value-added - are projected to serve numerous sectors, including new energy, high-end hydroelectric, super weathering bridge, high-grade chemical pressure vessel, high-strength mining machinery and Hadfield (high manganese alloy steel).

The Hongxing programme will rank JISCO as the top state-of-the-art, most competitive heavy plate production base in northwest China, with the most complete variety and specification of plate.

CISDI’s teams are committed to observing the programme’s principle of safety and quality first and bringing scheduling under control. Proficient in project management, design, construction and equipment manufacturing, they are CISDI’s most valuable resource.

The teams proposed and put in place systematic solutions and synchronised the customer and the partners.

CISDI focussed on including every production procedure and each milestone in the project’s standardised management and achieved 100% pass rates for the acceptance of critical and concealed works and of subdivisional works.

“We greatly appreciate CISDI handing over this demo project with no delays and no unresolved punch list items. The standards of its builds and services are benchmarks of Chinese efficiency and quality,” commented an executive at JISCO.

The heavy plate rolling line now operational at JISCO