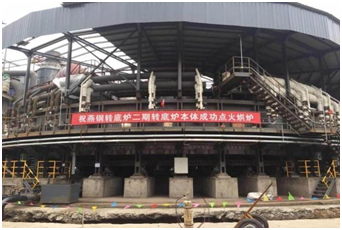

Yanshan Steel Phase II rotary hearth furnace dries off

Date:2018/8/28 Source: CISDI

The rotary hearth furnace for Yanshan Steel Phase II, the third of its

kind built by CISDI for China’s end-users, has been successfully dried off.

This is the second rotary hearth furnace built at the site by CISDI.

Each furnace has an annual capacity of 200,000 tonnes, in accordance with the

plant-wide iron-bearing solid waste output.

Work was carried out in two

phases and stretched from 2014 to 2018. The first rotary hearth furnace was

started up in 2015 and has been running smoothly for three years. It is working

so well that the plant has achieved zero iron-bearing solid waste discharge.

Technical indicators, energy consumption during each procedure and operation

costs excel those of other plants in China.

Phase I’s metallisation ratio of at least 70 per cent and

de-zincification ratio of a minimum of 85 per cent are standout indicators.

These results are credited to CISDI contributed expertise in

iron-bearing dust pelletising, drying efficiency, uniform distribution, hearth

atmosphere control, fast cooling and fume treatment.

Phase II, which was started up in August 2018, will consolidate the

plant-wide iron-bearing dust treatment capacity and will continue the zero

result in iron-bearing solid waste discharge.

CISDI is now a leading figure in

China’s rotary hearth furnace production. It has built three, including one for

Baosteel Zhanjiang, and owns some 40 patents for rotary hearth furnace-related

technology and equipment. It also holds two copyrights for process control and

operation software, and instruction manuals for the full production process.

The Phase II rotary hearth furnace in operation at Yanshan Steel

An aerial photograph of the Phase I rotary hearth furnace for Yanshan

Steel