Systematic optimisation

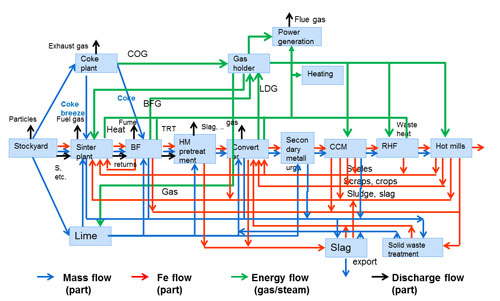

To optimise the systems of a steel plant, we study process procedures, interfaces and flows and analyse costs from five flows (mass flow, Fe flow, energy flow, discharge flow and information flow), and the rules of technology, management and economy are coordinated for a dynamic analysis. Our optimization proposals and methodology provide solid data methodology for decision-making, reduce costs and increase efficiency

The energy systematic optimization (ESO) is a method of competitiveness improvement through overall consideration of various energy flows in steel production process

Typical references

CISDI has supplied systematic optimization and consulting services for nearly 30 clients in China and abroad - with a total steel capacity of 160Mt/a.

Our services embrace plant-wide operations optimization, enterprise development planning, energy system optimization, individual system energy conservation planning, logistics system optimization and environmental improvement planning.

We have helped steel plants make energy consumption savings of up to 30kgce per tonne of steel and reduce their costs by as much as USD 6.25 per tonne of steel.。

• 0.84% increase of iron utilisation ratio for a certain steelworks, gaining an annual profit of about USD 2.05 millio

• Saving 34.3kg/t integrated energy consumption per tonne of steel for a certain steelworks, gaining an annual profit of about USD 60 million

• 1.5% increase of energy utilisation ratio for a certain steelworks, gaining an annual profit of about USD 47 million